Description

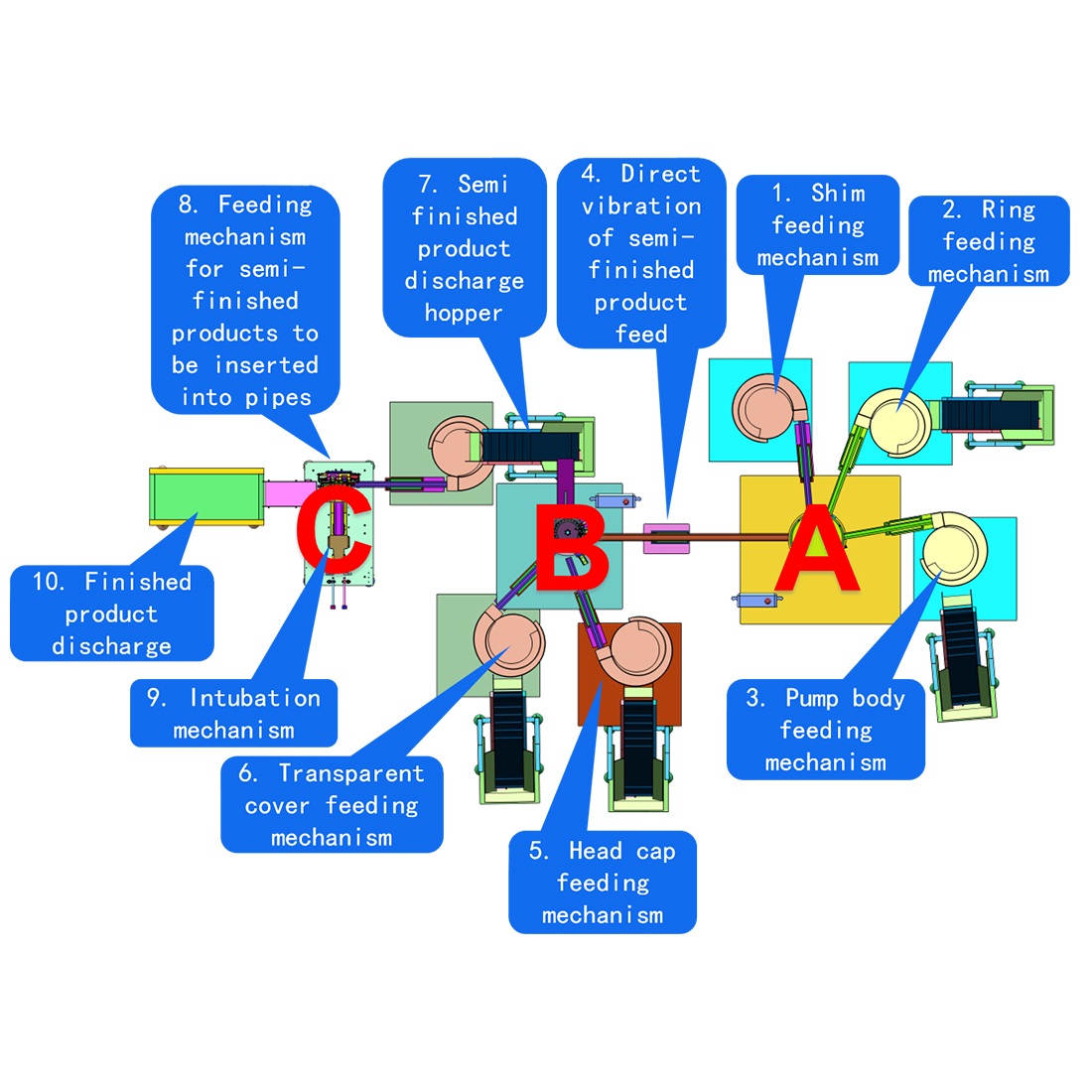

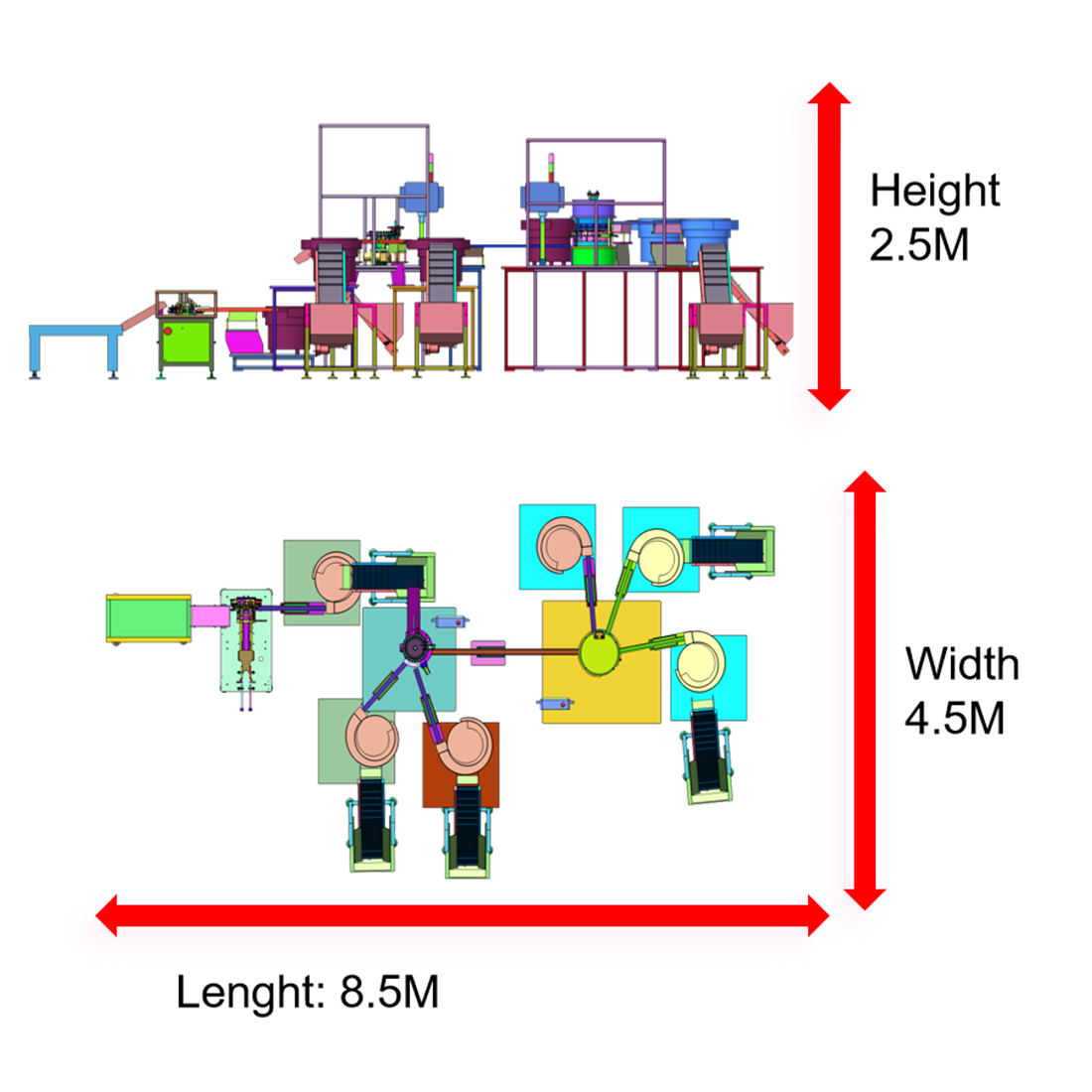

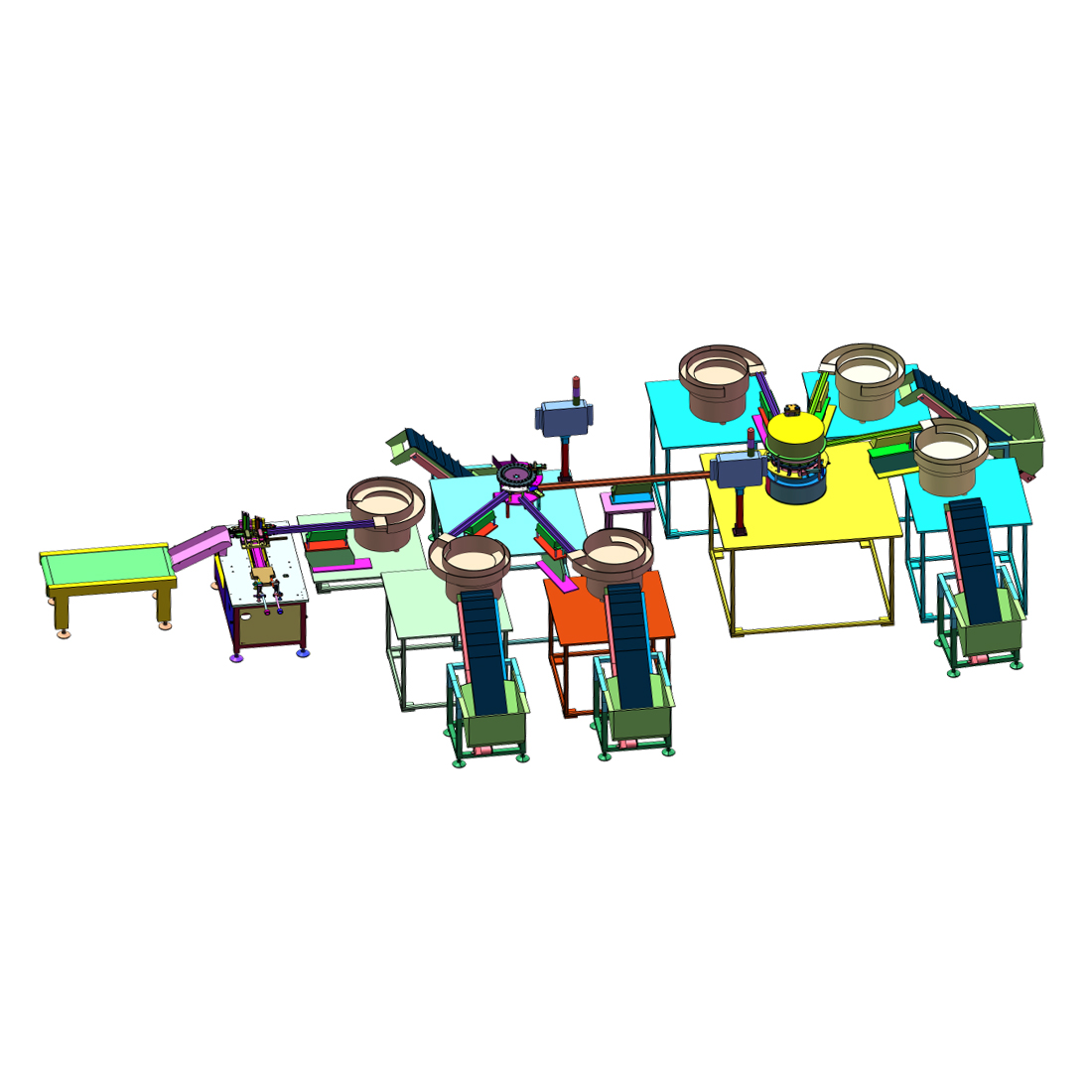

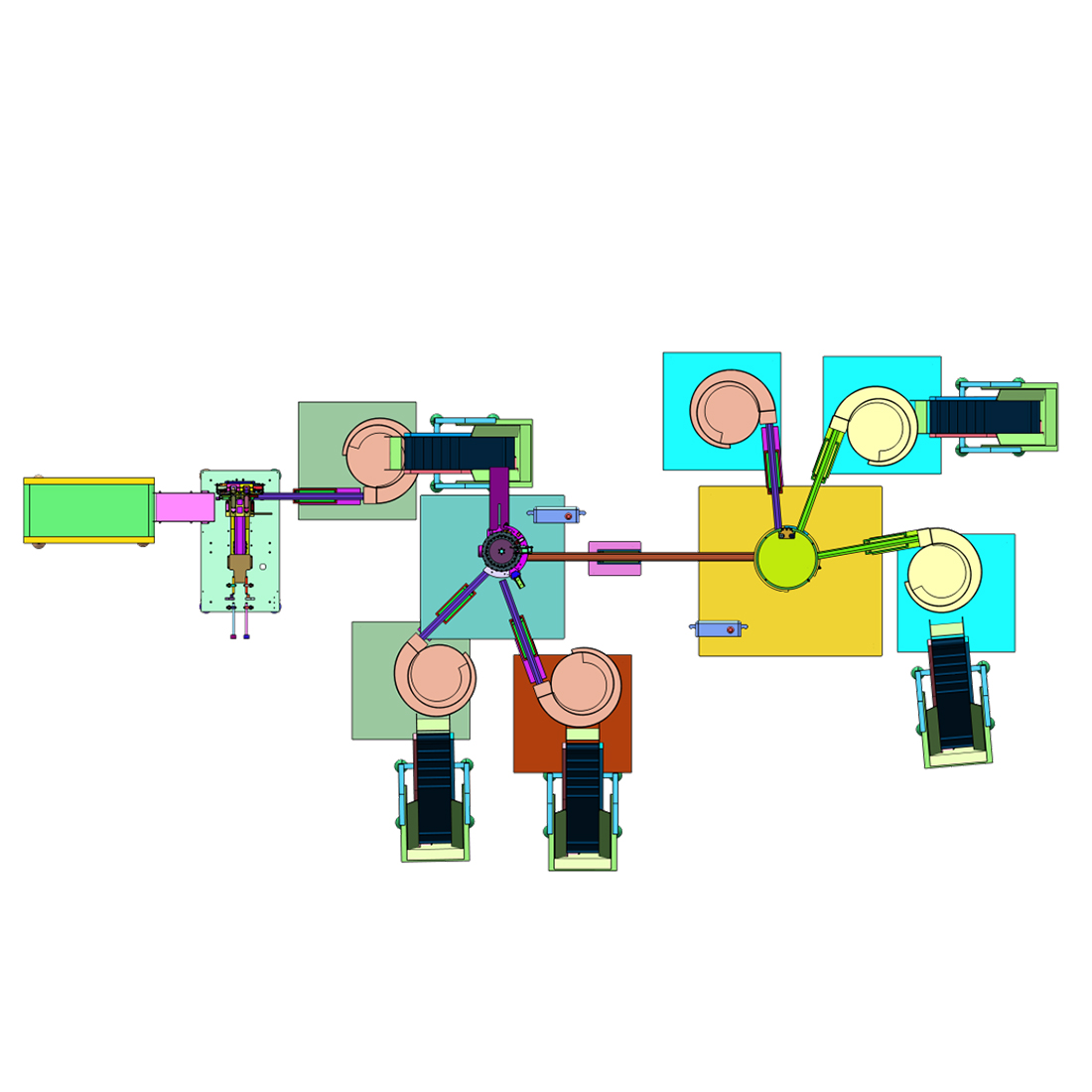

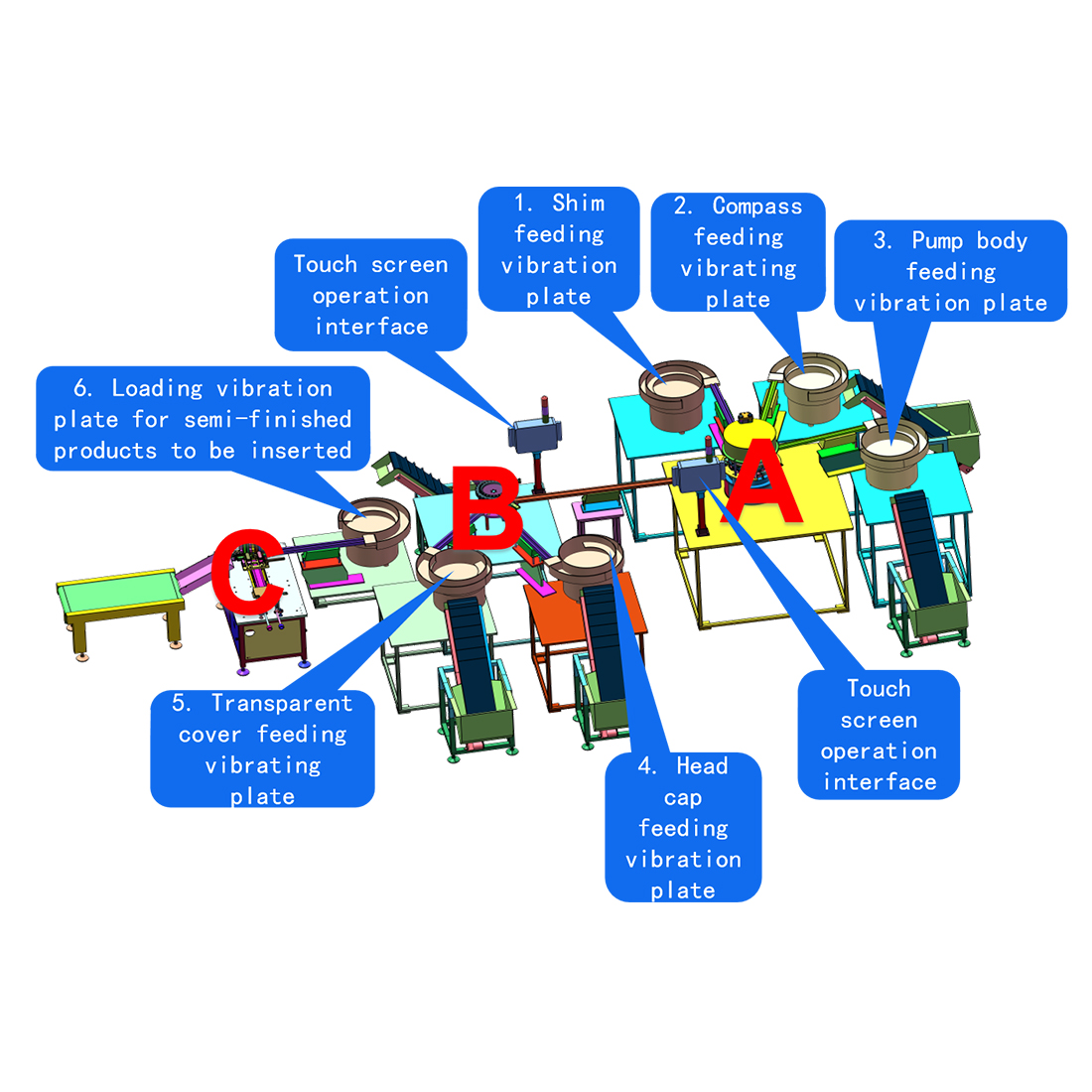

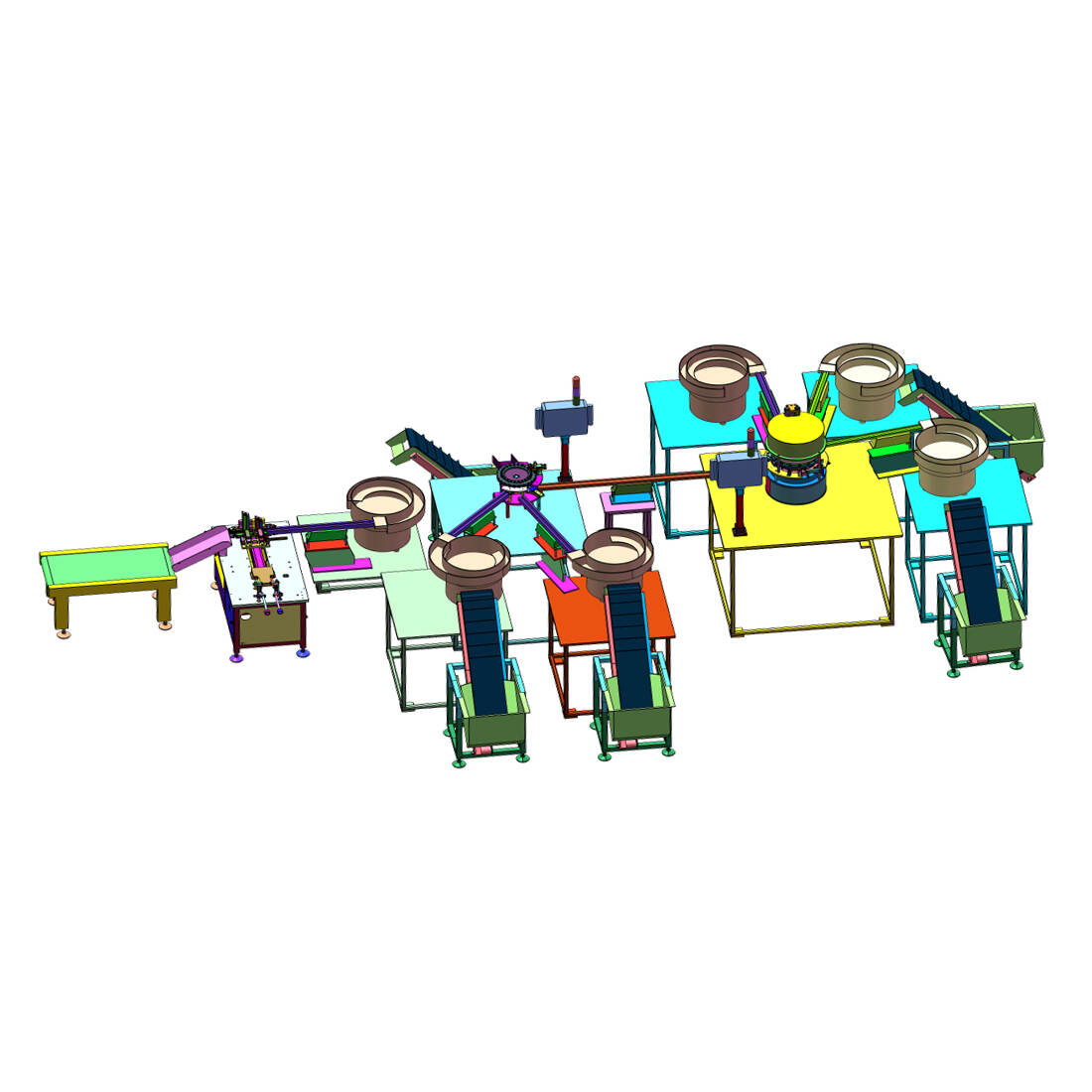

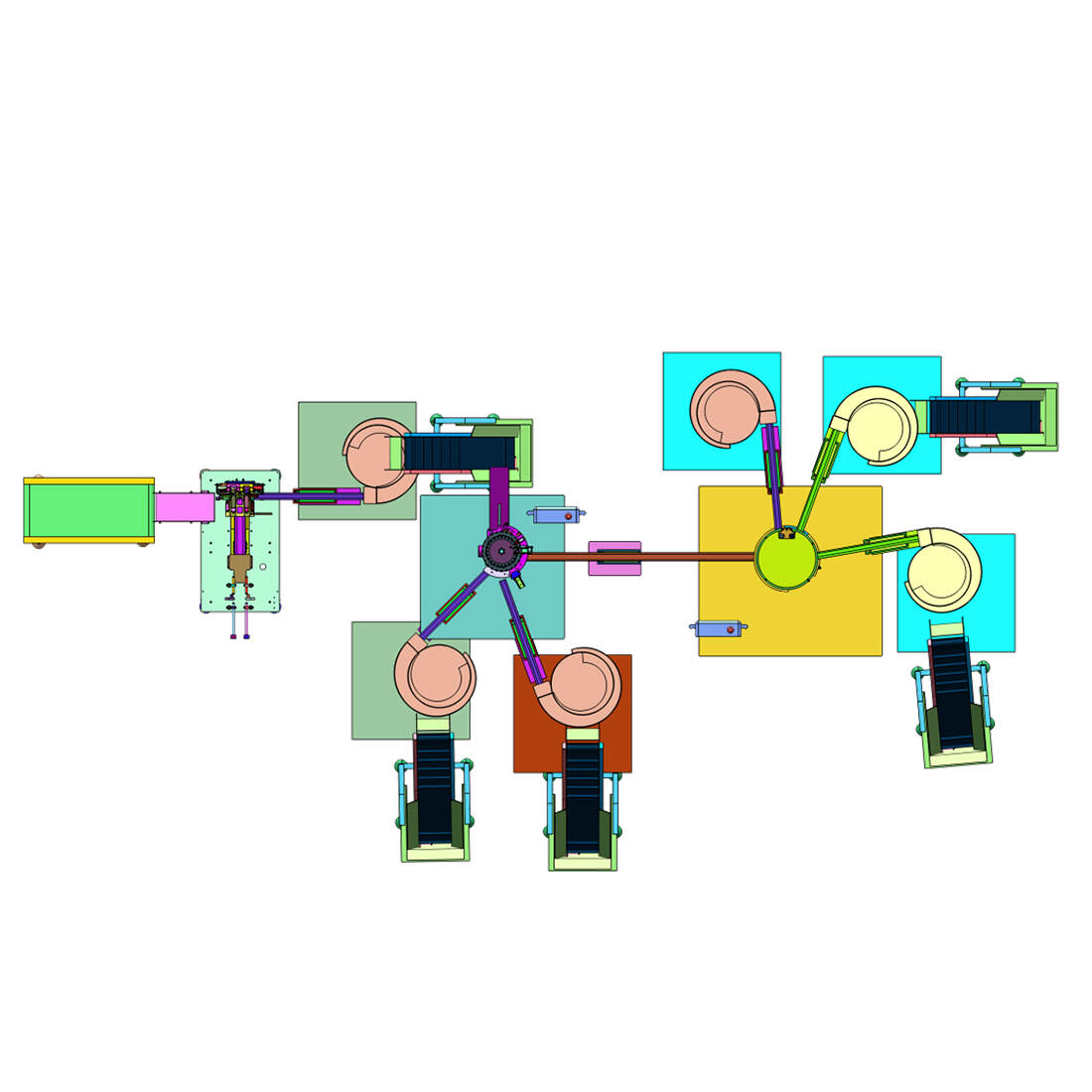

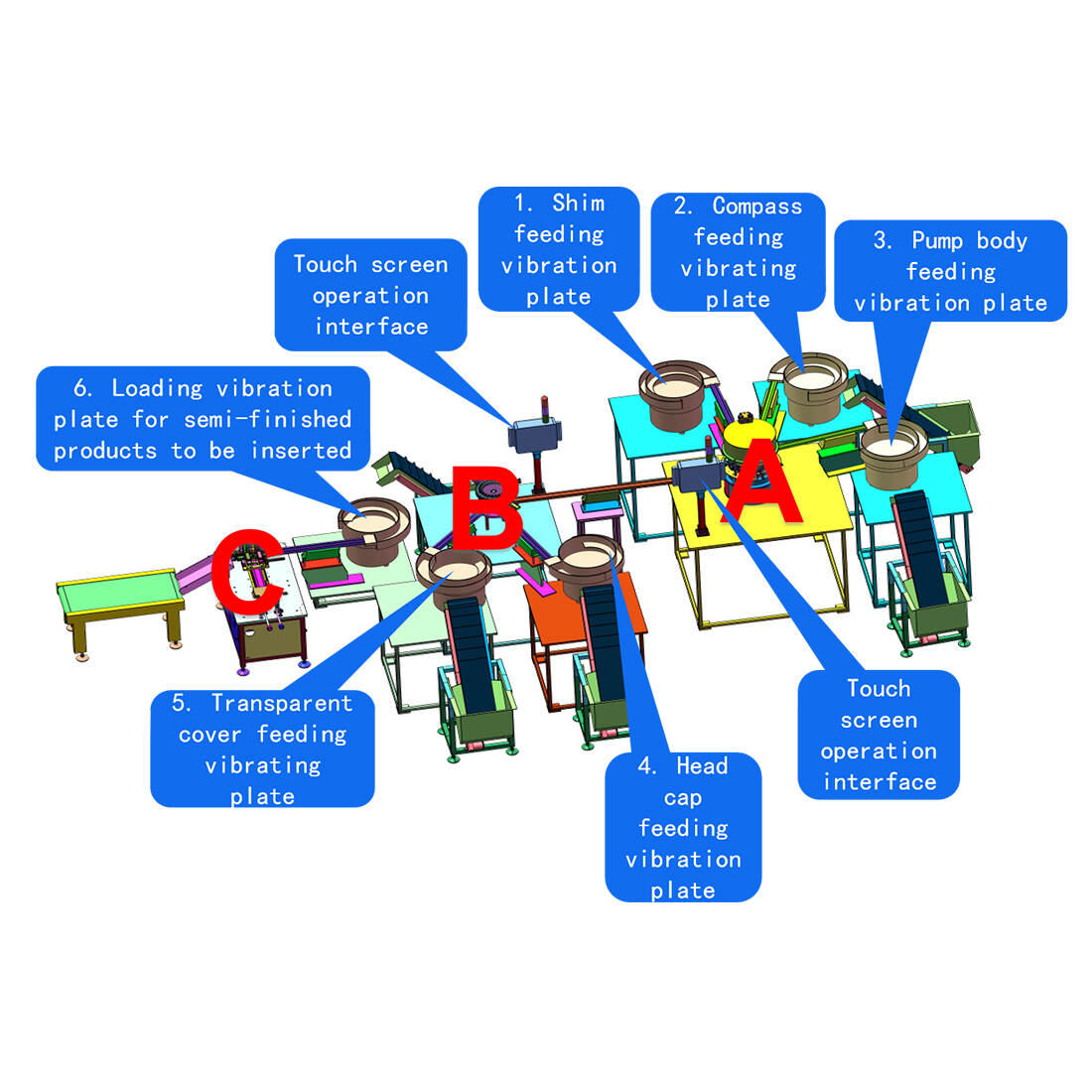

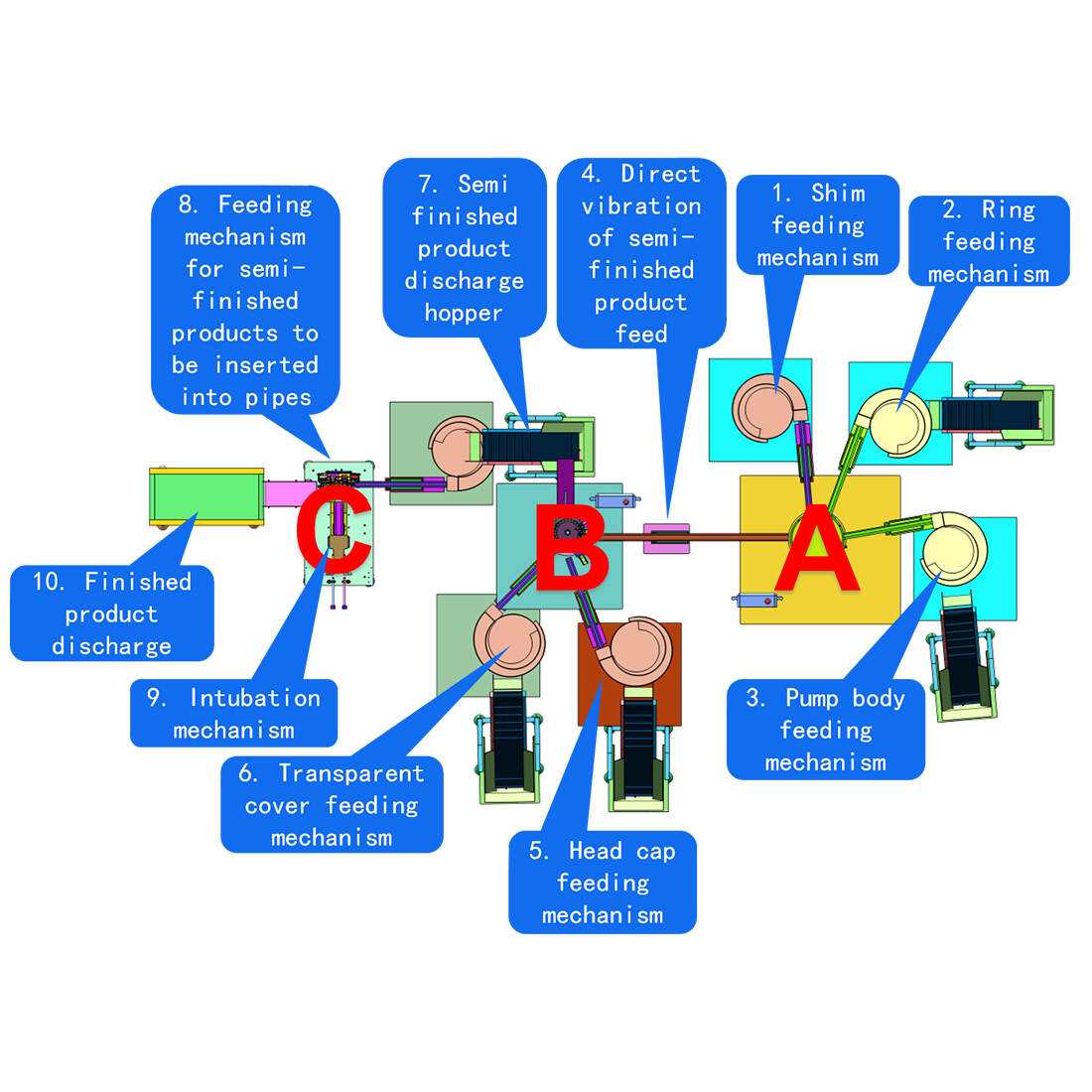

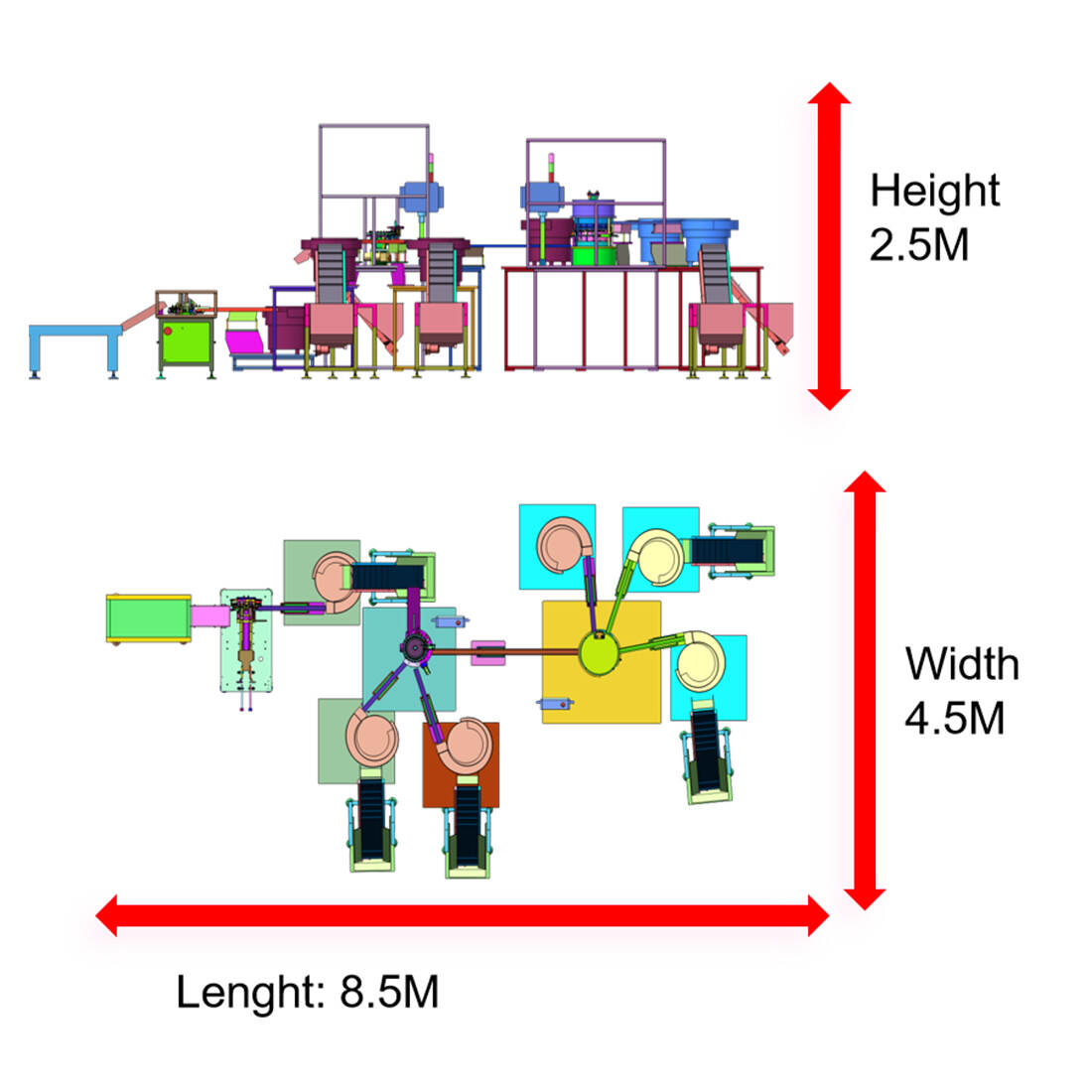

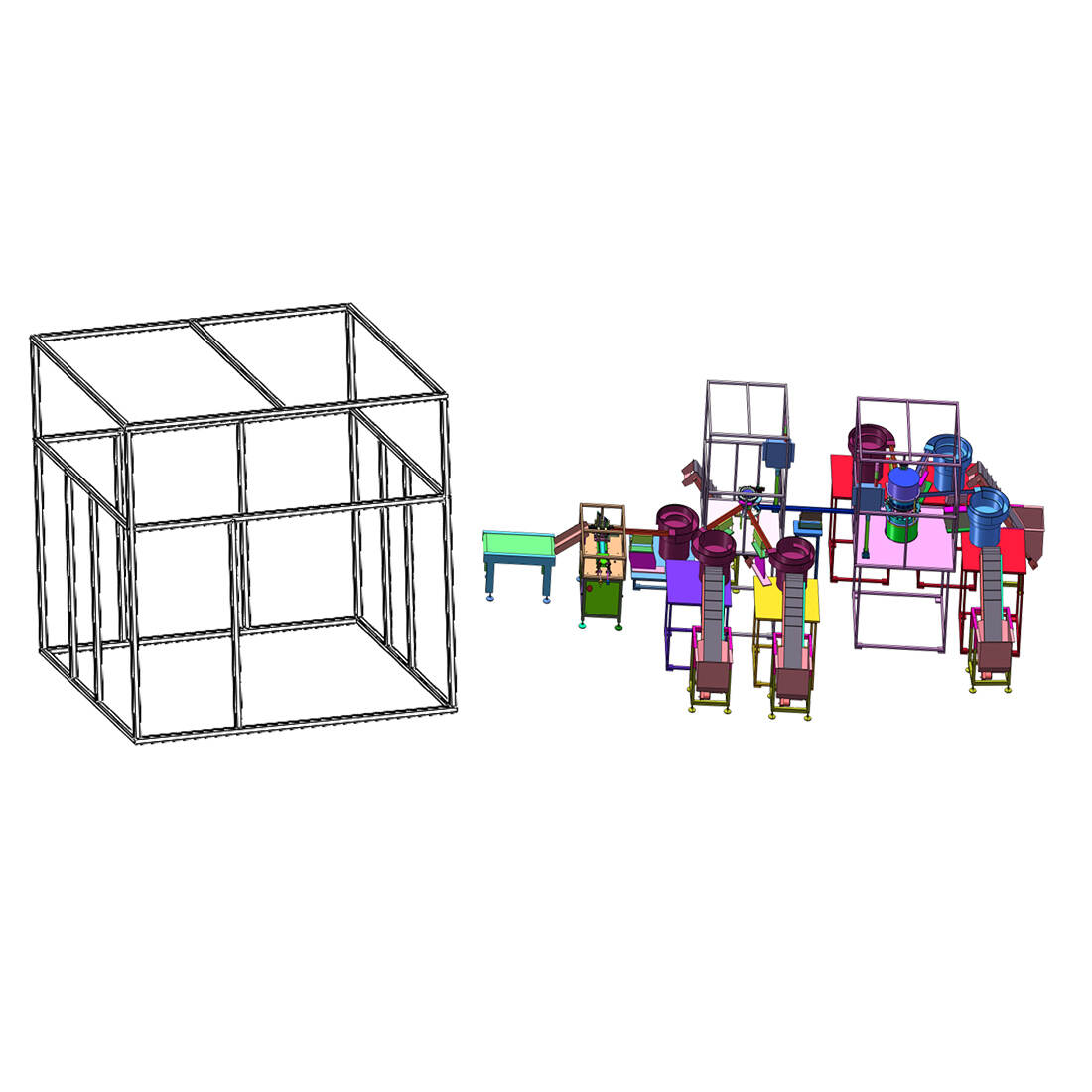

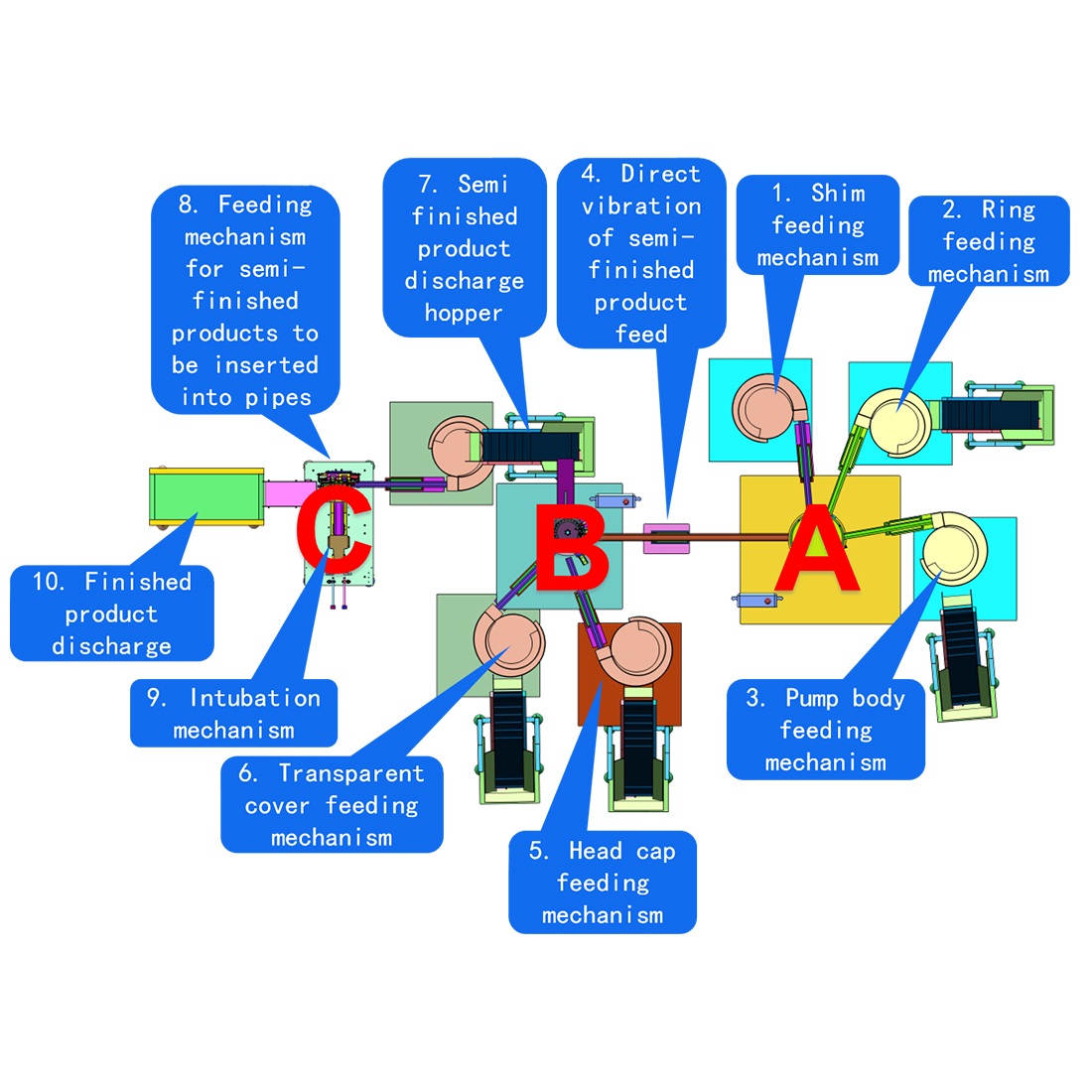

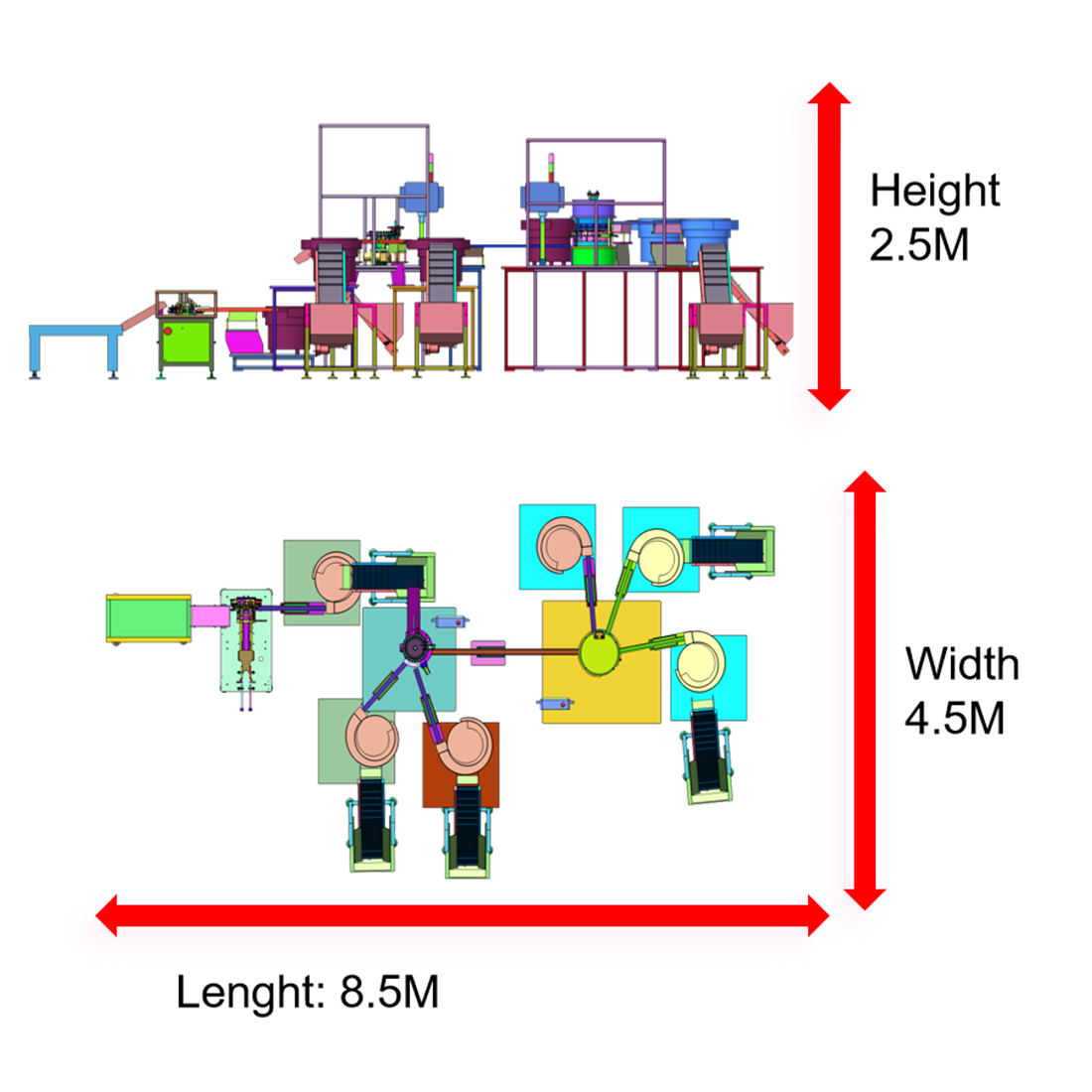

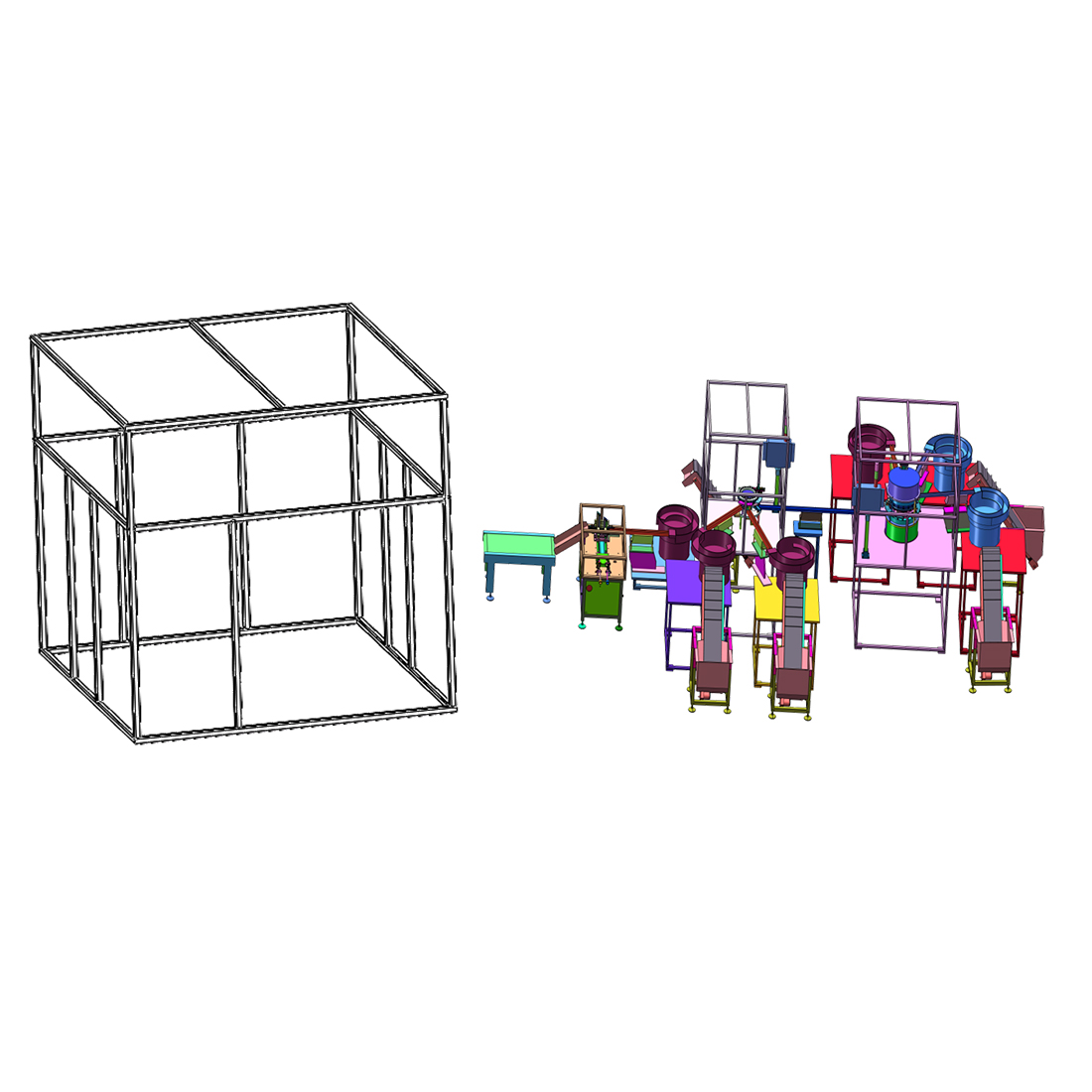

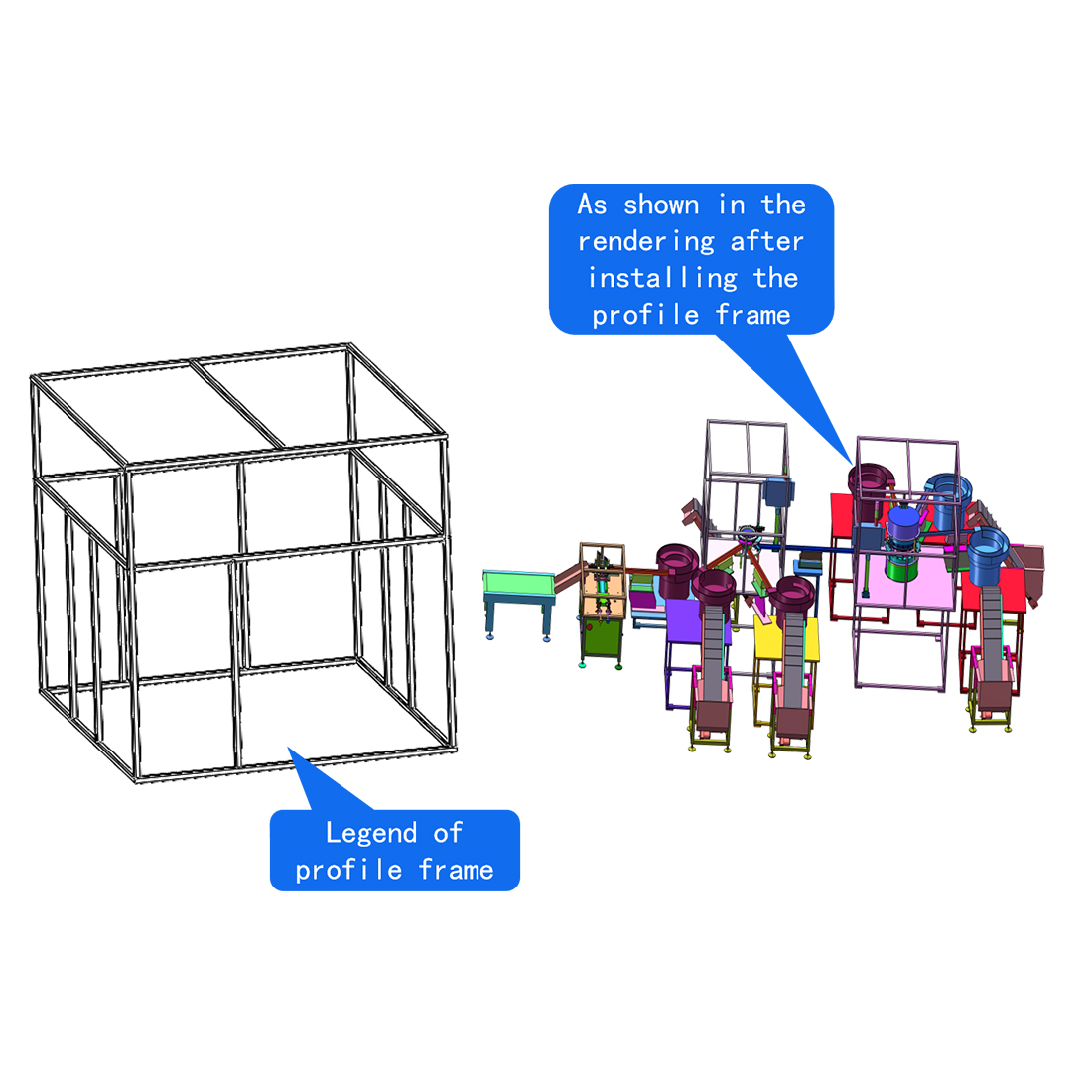

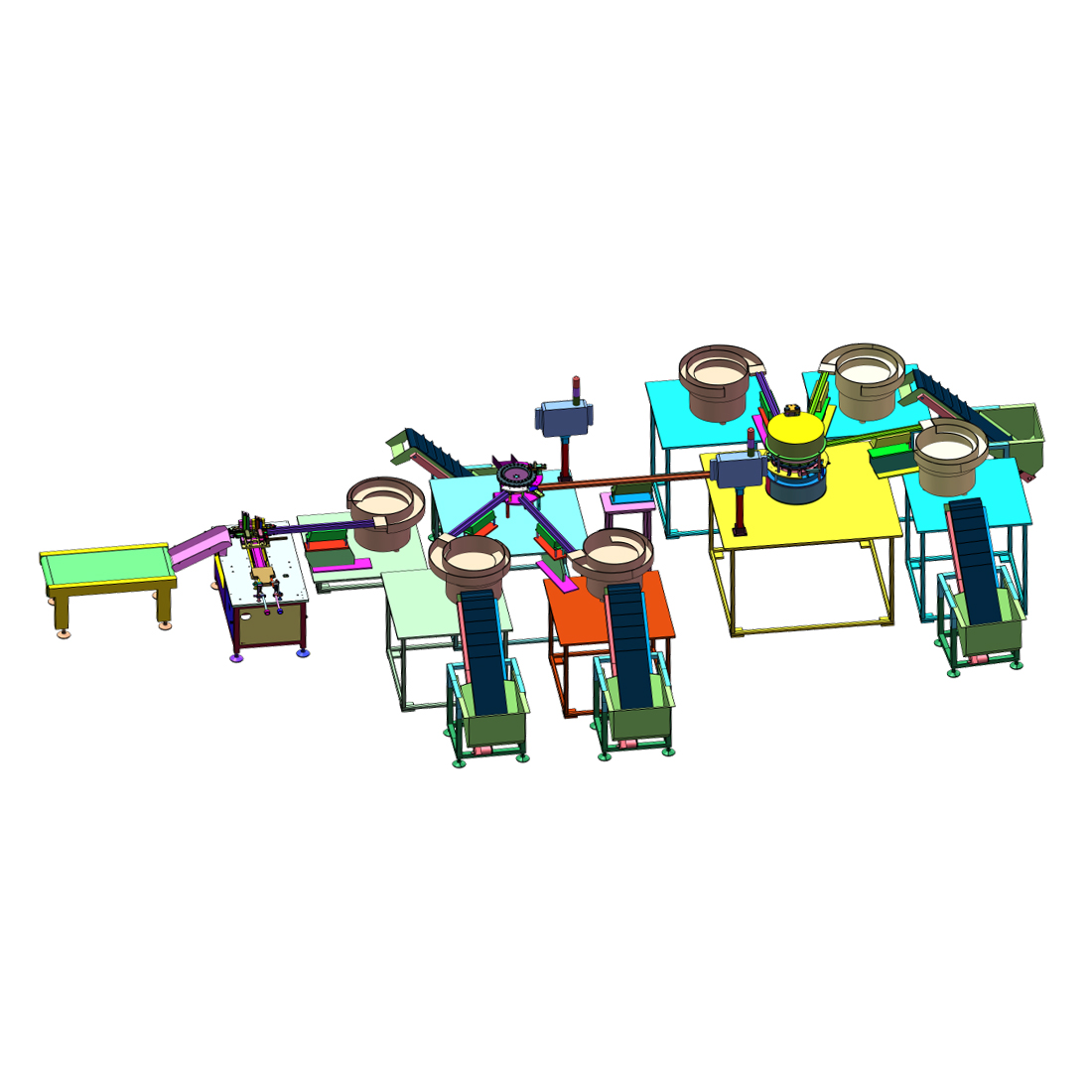

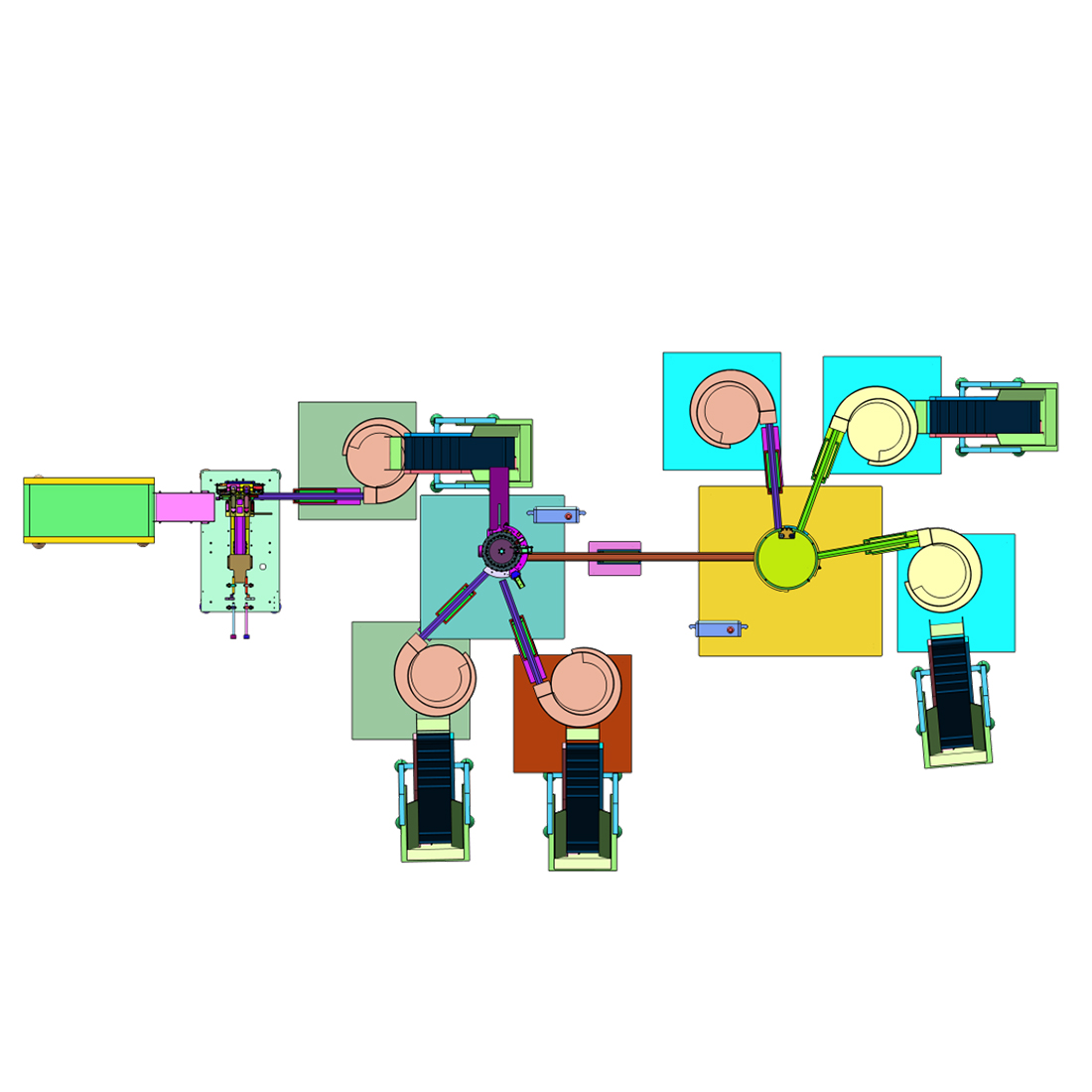

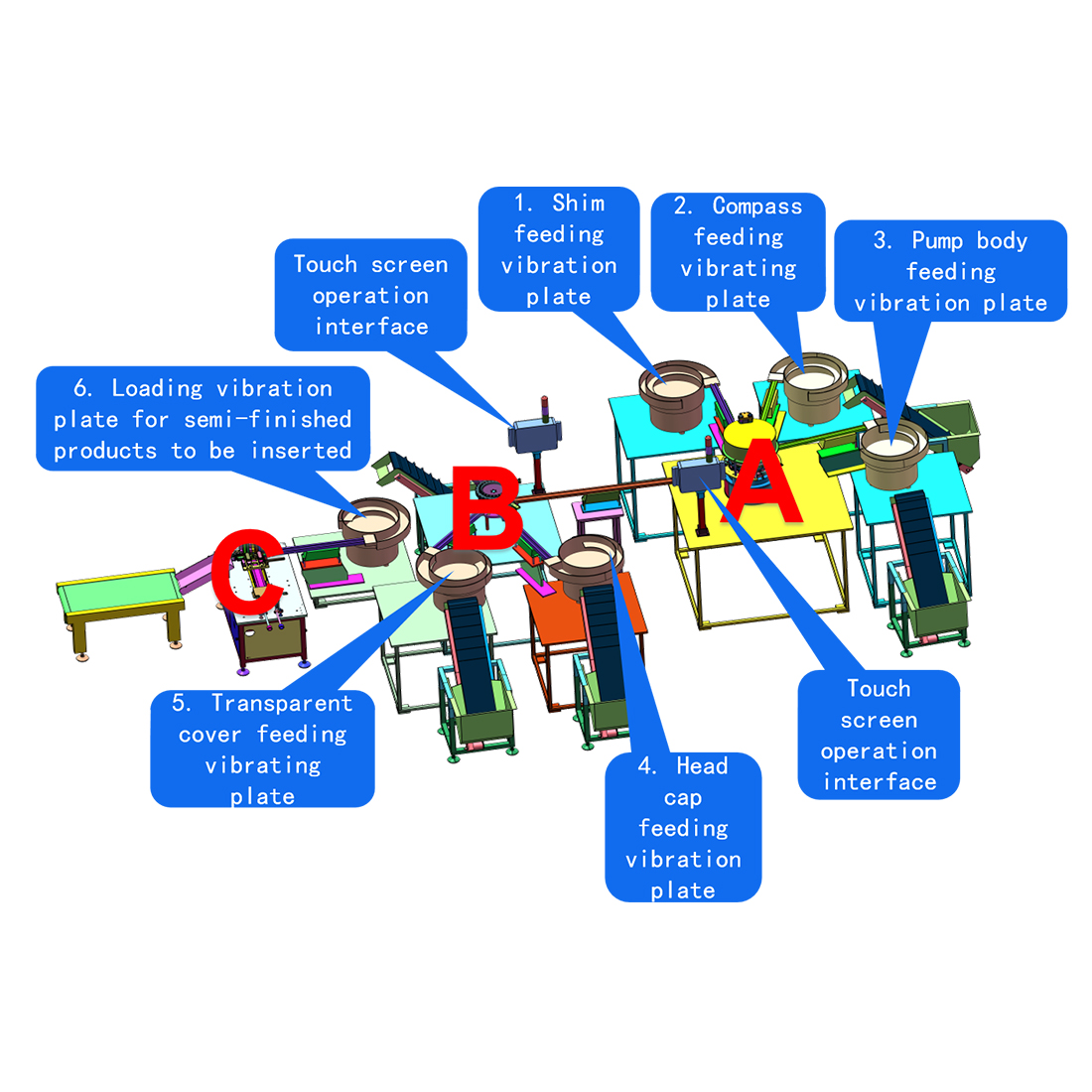

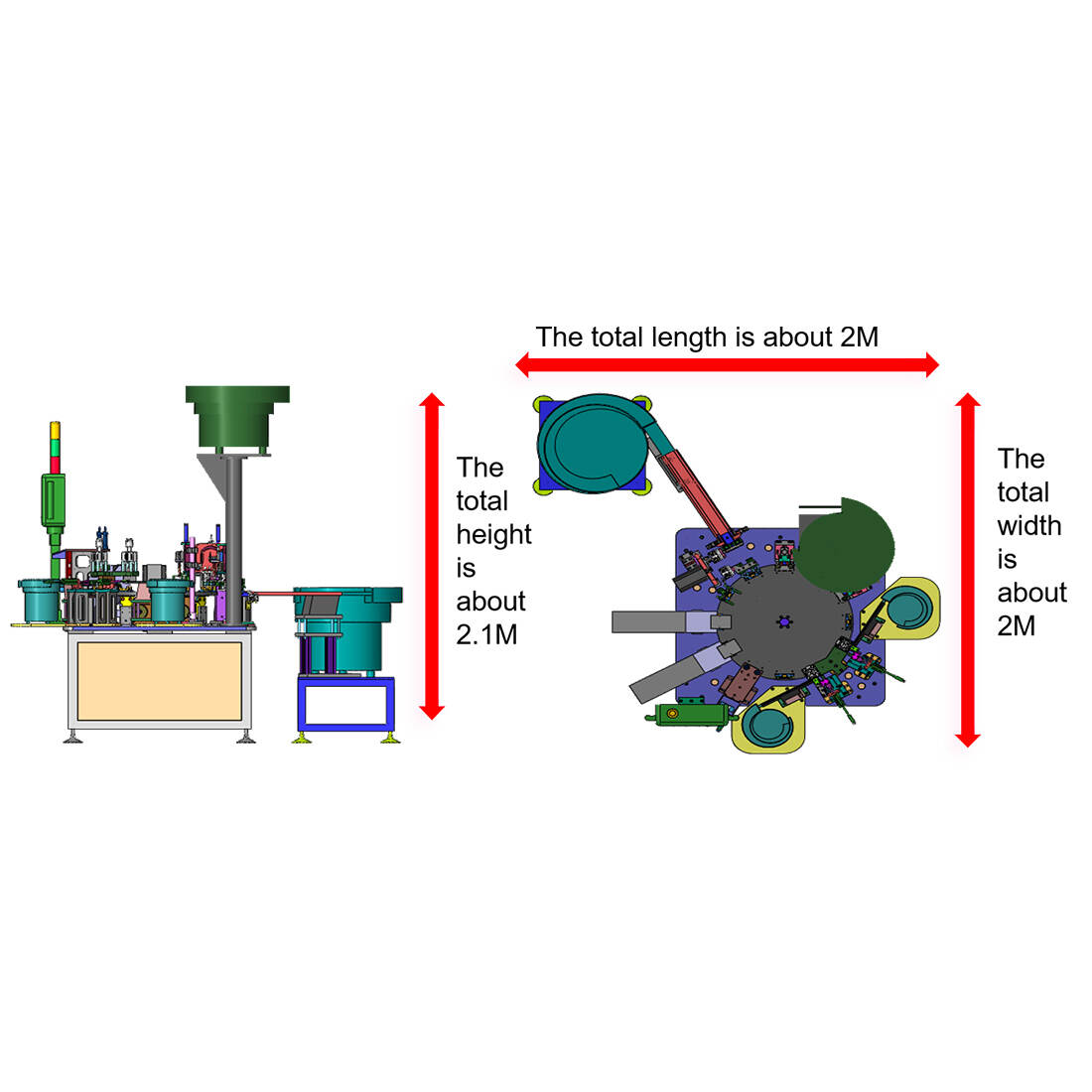

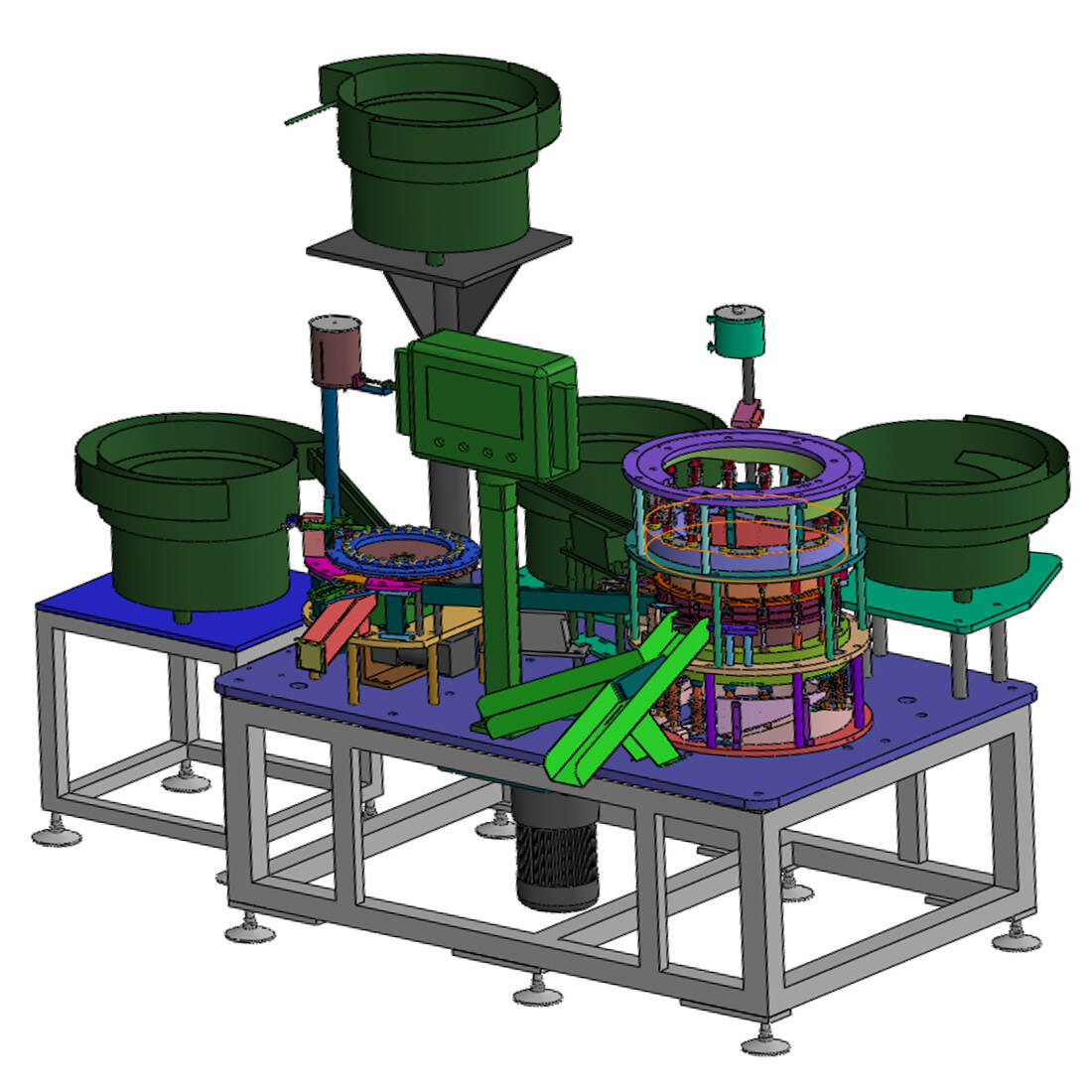

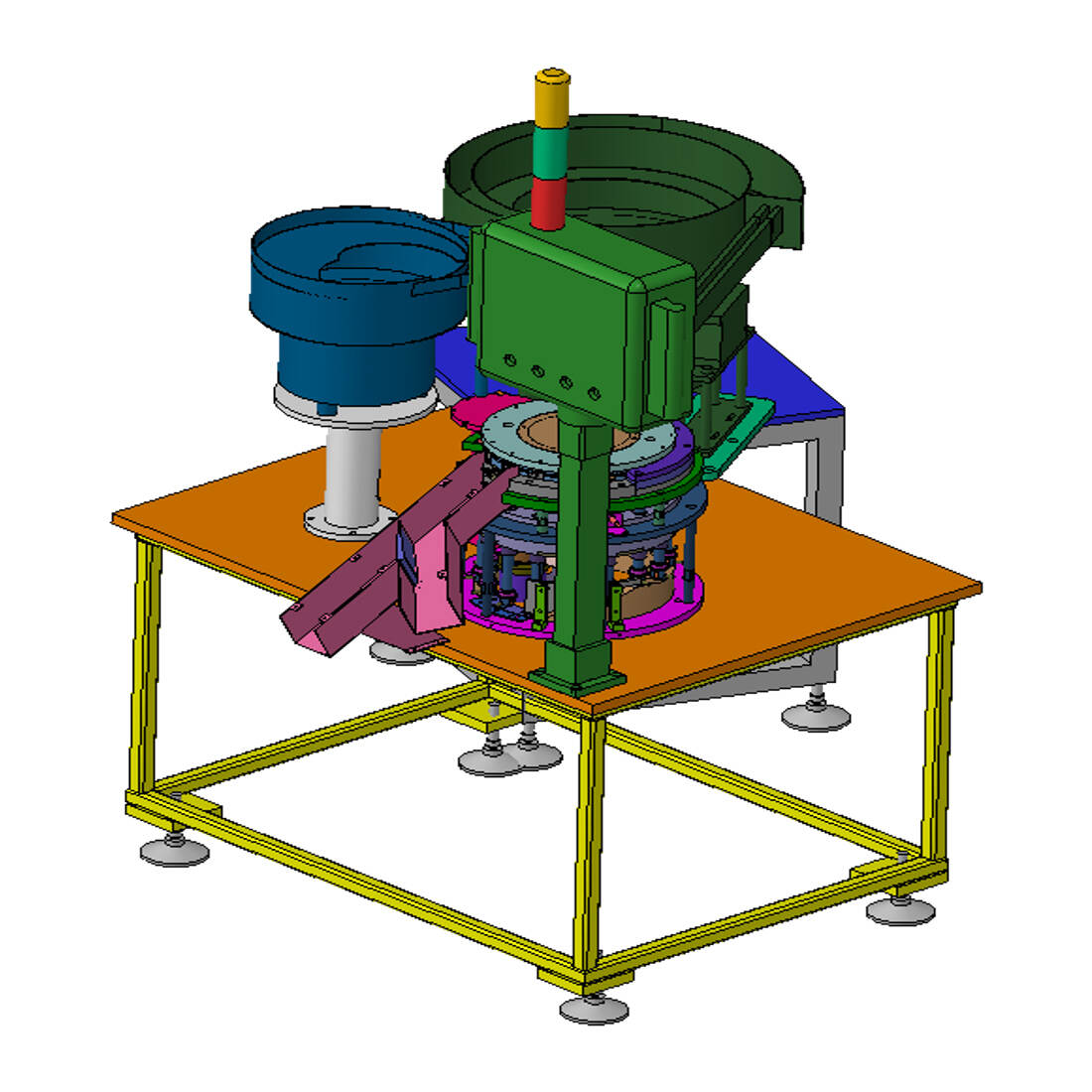

The Mist Spray High-Speed Assembly and Intubation Equipment is designed for efficient and precise assembly of mist sprayer components, specifically targeting the assembly of trigger sprayer covers and tube inserts. With dimensions of 2.5 m in height, 8.5 m in length, and 4.5 m in width, this equipment is tailored to handle high-volume production demands while ensuring product quality and reliability. The system integrates advanced detection mechanisms to guarantee accurate assembly and inspection of each component.

Product Specification

- Voltage:220V

- Power:5KW

- Air Pressure:0.6Mpa

- Machine L*W*H:8.5*4.5*2.5

Product Features and Advantages of Mist Spray High-Speed Assembly and Intubation Equipment

1. High-Speed Operation:

Capable of rapid assembly, significantly boosting production efficiency.

Suitable for large-scale manufacturing environments requiring continuous operation.

2. Precision Assembly:

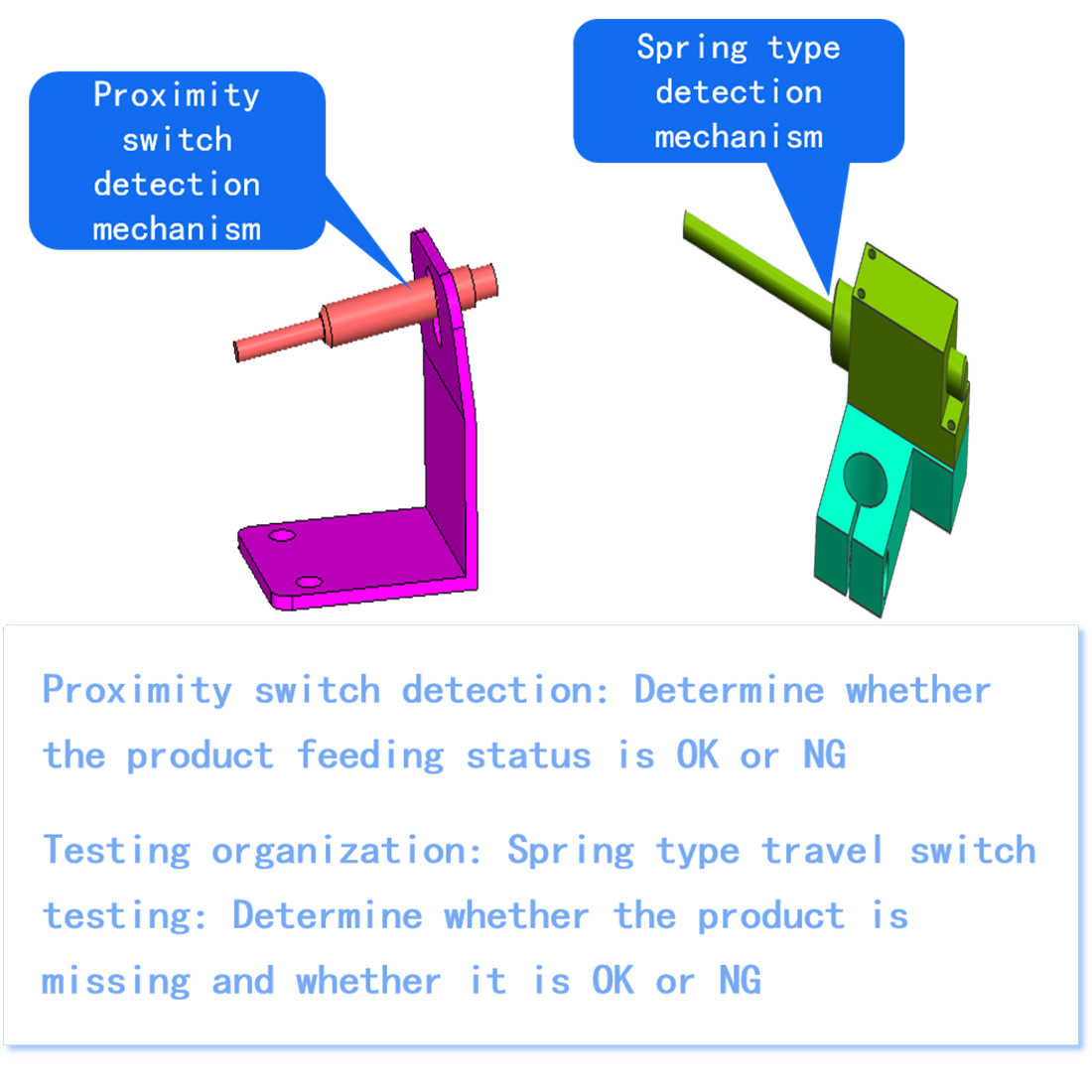

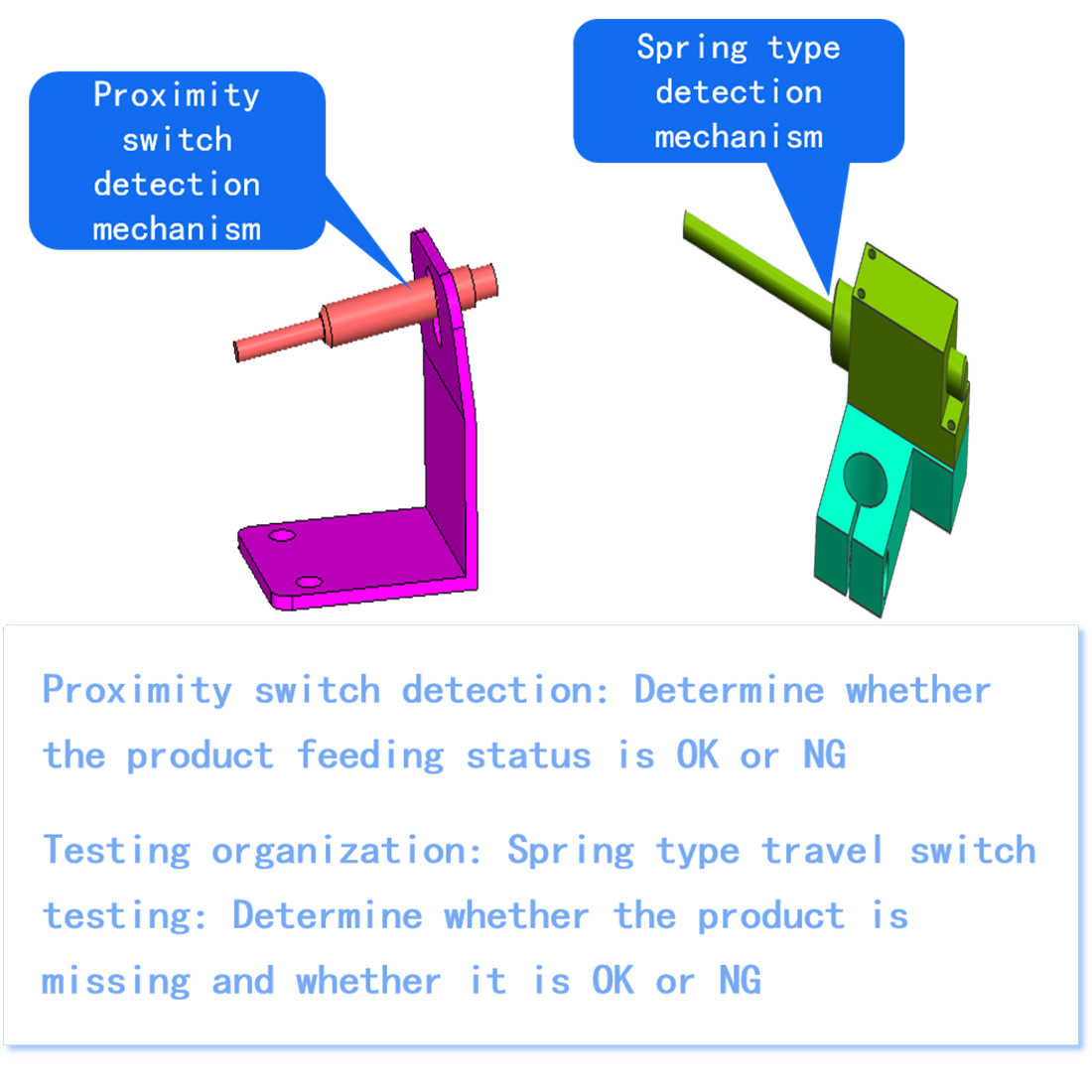

Utilizes proximity switch detection mechanisms to ensure correct product feeding.

Equipped with a spring-type travel switch to detect missing or improperly assembled components.

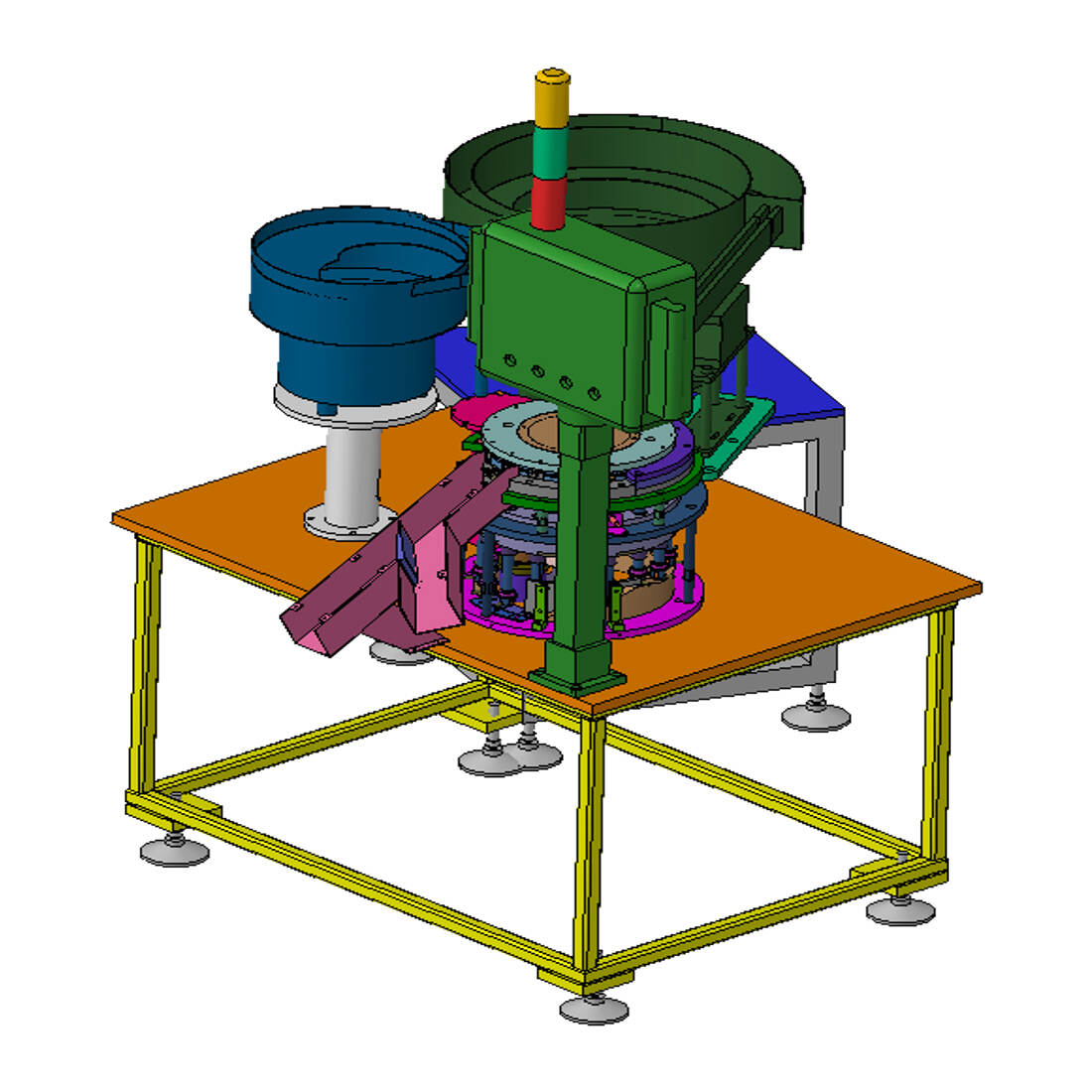

3. Robust Construction:

Built with durable materials to withstand intensive industrial use.

Designed to operate reliably over extended periods with minimal maintenance.

4. Advanced Detection Mechanisms:

The proximity switch detection mechanism verifies the status of product feeding, ensuring only correctly fed products proceed to the next stage.

A spring-type detection mechanism assesses the completeness of the assembly, identifying and rejecting faulty products.

5. Versatile Application:

Suitable for various mist sprayer models, offering flexibility in production.

Adjustable settings accommodate different sizes and types of trigger sprayer covers and tubes.

Benefits

1. Increased Productivity:

The high-speed assembly capabilities drastically reduce production time, allowing manufacturers to meet high demand effectively.

2. Enhanced Quality Control:

Integrated detection mechanisms ensure only properly assembled components are processed, reducing the risk of defects.

3. Cost Efficiency:

By minimizing errors and reducing the need for rework, the equipment helps lower overall production costs.

4. Reduced Downtime:

The robust construction and automated diagnostics contribute to lower maintenance needs and uninterrupted operation.

5. Scalability:

The machine's versatile design makes it suitable for scaling production up or down based on demand, providing manufacturers with the flexibility to adapt to market changes.